Custom Silicone Products Manufacturer

100% Food-Grade Silicone Products| BPA-Free, Eco-Friendly & Non-Toxic

Product Categories

Our silicone products are widely used across various sectors such as consumer goods, industrial and medical, recognized for innovative customization and professional manufacturing expertise.

Shenzhen Xinyin Environment Rubber Products Co., Ltd.

A leading manufacturer of silicone rubber and polymer elastomer materials since 2005. With over 20 years of industry expertise, we operate modernized facilities spanning 6,000+ sqm across Shenzhen and Dongguan.

Our vertically integrated production system features 30+ advanced equipment and a 100+ skilled workforce, ensuring precision manufacturing from procurement to rigorous quality control. Committed to safety and eco-friendly innovation.

Our Services

We provide end-to-end support from concept to market for our partners, making us a preferred choice for renowned silicone product brands and retailers.

- One-stop ODM/OEM Customized Service

- Free Sample Service

- Material Selection and Certification Consulting Service

- Supply Chain and Production Support Service

- Brand Packaging and Personalized Service

- One-year Warranty and After-sales Service

Capabilities

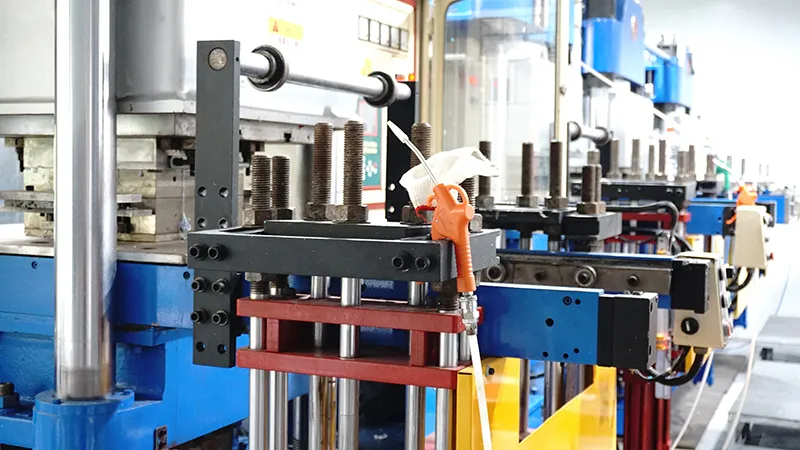

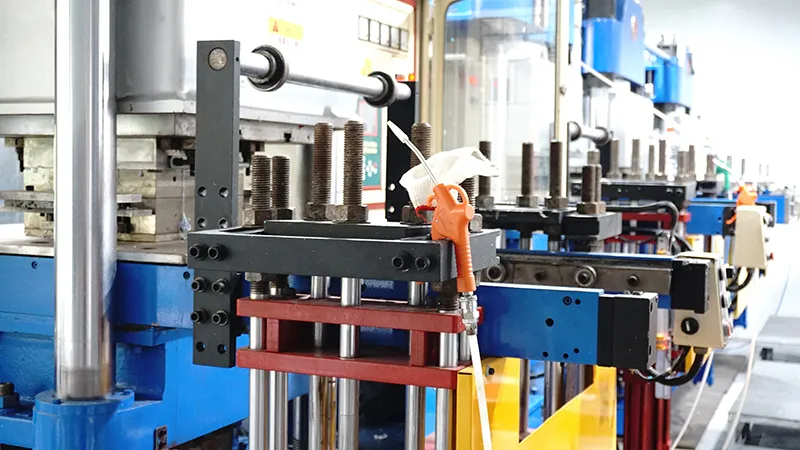

Silicone Compression Molding

The compression molding widely used in medical and sanitary products except for Industrial, daily necessities (such as silicone housewares, kitchenware, silicone gifts, etc.), baby products and other fields that require high levels of safety and environmental protection.

Liquid Silicone Rubber Injection (LSR)

LSR molding technology is used to manufacture durable, flexible, high-precision, high-quality, and highly water and corrosion-resistant parts, and it enables high-volume production. It allows for high output, fast cycle times, automated processing, and the manufacturing of complex shapes.

Therefore, due to their precise dimensional characteristics, LSR molded parts are ideally suited for use as seals, diaphragms, electrical connectors, and various other applications in the medical, commercial, and household sectors.

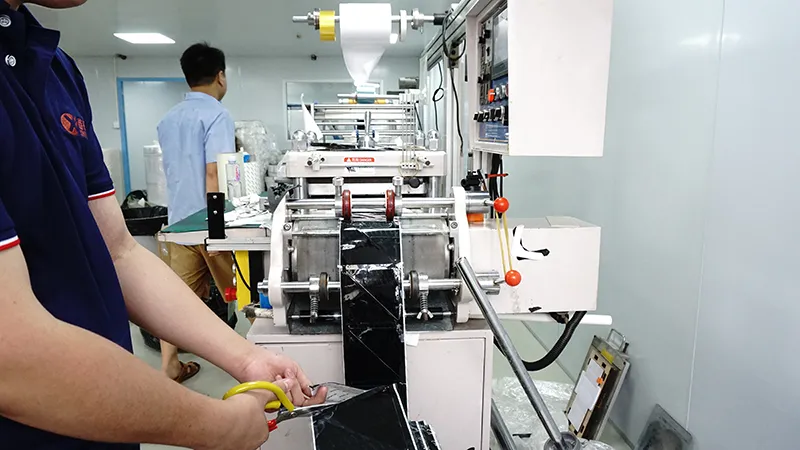

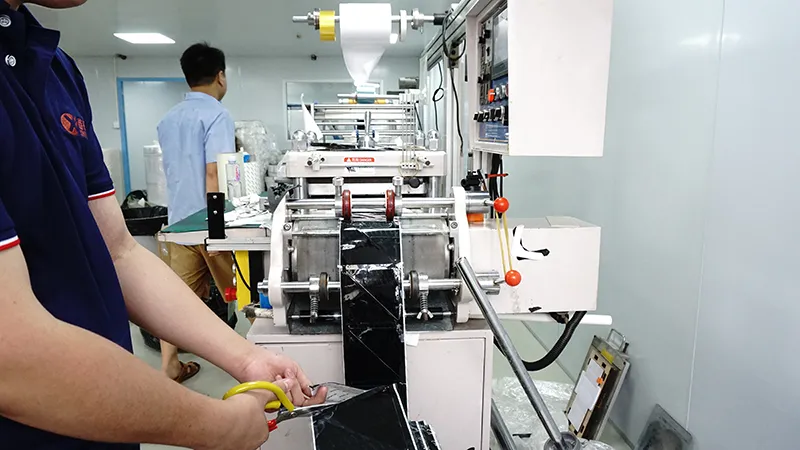

Silicone Fabric Coating And Curing

Silicone fabric Coating and curing: Uncured silicon is made into a film of a certain thickness with a roller. coated on the fabric, and then completely hardened by pressing the silicon surface with a heat roller having a specific pattern, And a step of coating with a surface treating agent after the above-mentioned process.

Then to get the silicone products to various desirable properties, such as water resistance, heat resistance, and hydrolysis resistance qualities.

Silicone Extrusion Molding

Silicone Extrusion Molding is a continuous manufacturing process where uncured silicone rubber is forced through a shaped die under high pressure. This forms the material into a long, continuous profile with a consistent cross-section, such as tubes, seals, cords, or custom shapes.

The extruded silicone then undergoes vulcanization (curing) using heat, resulting in a durable, flexible, and resilient final product with excellent sealing, insulation, and temperature resistance properties.

The compression molding widely used in medical and sanitary products except for Industrial, daily necessities (such as silicone housewares, kitchenware, silicone gifts, etc.), baby products and other fields that require high levels of safety and environmental protection.

LSR molding technology is used to manufacture durable, flexible, high-precision, high-quality, and highly water and corrosion-resistant parts, and it enables high-volume production. It allows for high output, fast cycle times, automated processing, and the manufacturing of complex shapes.

Therefore, due to their precise dimensional characteristics, LSR molded parts are ideally suited for use as seals, diaphragms, electrical connectors, and various other applications in the medical, commercial, and household sectors.

Silicone fabric Coating and curing: Uncured silicon is made into a film of a certain thickness with a roller. coated on the fabric, and then completely hardened by pressing the silicon surface with a heat roller having a specific pattern, And a step of coating with a surface treating agent after the above-mentioned process. Then to get the silicone products to various desirable properties, such as water resistance, heat resistance, and hydrolysis resistance qualities.

Silicone Extrusion Molding is a continuous manufacturing process where uncured silicone rubber is forced through a shaped die under high pressure. This forms the material into a long, continuous profile with a consistent cross-section, such as tubes, seals, cords, or custom shapes. The extruded silicone then undergoes vulcanization (curing) using heat, resulting in a durable, flexible, and resilient final product with excellent sealing, insulation, and temperature resistance properties.

Advanced Production Equipment

We are equipped with a complete set of production facilities, including silicone die-cutting machines, molding presses, calenders, coating machines, electronic tensile testing machines, insulation resistance testers, horizontal burning test machines, and liquid silicone rubber molding machines.

Our one-stop service eliminates the risks of cooperating with multiple suppliers, saving your time and reducing costs. The daily output reaches approximately 150,000 to 200,000 pieces, with products exported to over 40 countries worldwide.

Company Advantages

We provide end-to-end support from concept to market for our partners, making us a preferred choice for renowned silicone product brands and retailers.

20 Years of Manufacturing Experience

With 20 years of experience in silicone product manufacturing, we have accumulated profound expertise in quality control and market insights. This enables us to possess advanced R&D and production technologies, as well as a deep understanding of the product and market requirements of different wholesale clients.

One-Stop Customization Services

Xinyin provides comprehensive OEM/ODM services and various wholesale customization solutions to meet your diverse design and product needs. Customizable options include materials, patterns, sizes, colors, and branded packaging.

Strict Quality Control

XY implements a rigorous full-cycle quality control system from silicone product development to final delivery. We ensure clients receive qualified silicone prototypes for approval before mass production, committed to delivering satisfactory high-quality products.

Integrated Packaging & Logistics Services

We assist you in selecting optimal packaging solutions tailored to your budget, product type, and shipping requirements. Ultimately, we guarantee that silicone products are delivered to you in the best possible condition.